| Product Name: | LP Series Hygienic Lobe Pumps |

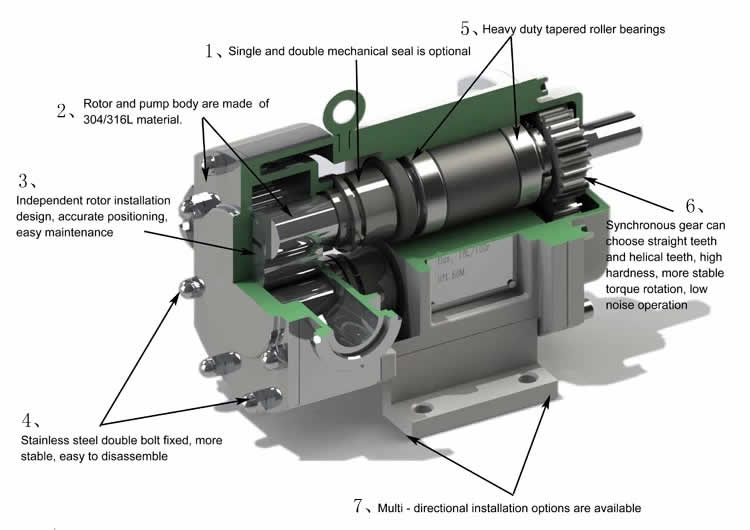

| Material Science: | SS304 / SS316L |

| sealing material: | EPDM (Standard, FDA Approval) |

| Maximum flow: | 2~1110GPM |

| Maximum pressure: | 4~10bar |

| Maximum permissible fluid temperature: | 100°C(212°F)/ 200°C(392°F) -water-cooling |

| Specification of power supply: | 110V,220V,240V,380V,400V,415V,440V 50hz / 60hz |

| Connection type: | Fast clamping, flange, thread, SMS, barb, square port |

| Motor power: | 1~30kw |

| Entry/Exit location: | Horizontal or vertical |

| Maximum viscosity: | 1×1000000CST |

| Optional criteria: | DIN,SMS,3A,RJT,ISO / IDF |

| Scope of application: | Dairy products, food, beverages, pharmacies, cosmetics, etc. |

| Maximum diameter: | 1"/1.2"/1.5"/2"/2.5"/3"/4"/6" |

| Rotor type: | Single leaf, double leaf, three leaf, four leaf, axe head, spiral |

| Sealing material: | EPDM (standard, FDA approved) |

| Sealing options: | PTFE/hygienic single mechanical seal / double mechanical seal with cooling system |

| Packaging details: | Plywood box or custom. Or according to customer |

|

Model

|

DISPLACEMET

LITER/REV

|

NOMLNAL

LONNECTION

SIZE

|

DIFFERENTIAL

PRESSURE RATING

BAR

|

MAXIMUM

PUMP SPEED

RPM

|

INPUT SHAFT

DIAMETER

(MM)

|

MAXIMUM

TORQUE

N-M

|

|

LP-6

|

0.06

|

25(1")

|

10

|

960

|

19

|

108

|

| LP-9 | 0.09 |

32(1.2")

|

10

|

960 | 19 |

108

|

|

LP-18

|

0.18

|

40(1.5")

|

10

|

960

|

21

|

166

|

|

LP-36

|

0.36

|

50(2")

|

10

|

720

|

28

|

244

|

|

LP-60

|

0.6

|

65(2.5")

|

10

|

720

|

38

|

444

|

|

LP-135

|

1.35

|

80(3")

|

10

|

600

|

48

|

832

|

|

LP-250

|

2.5

|

100(4")

|

10

|

600

|

60

|

1665

|

|

LP-535

|

5.35

|

150(6")

|

10

|

400

|

75

|

2800

|

|

LP-700

|

7

|

150(6")

|

10

|

400

|

75

|